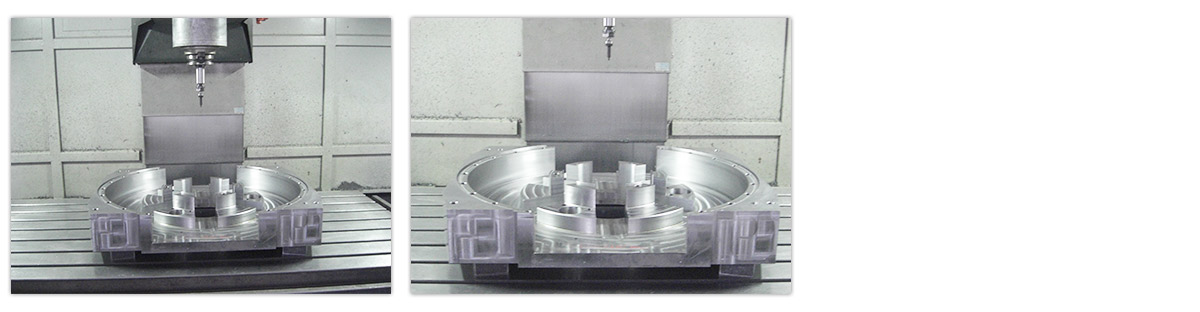

Precision CNC Turning & Milling of Welding Fixture

At HLF, we provide custom CNC machining services to Customers in a wide range of industries. This cover is produced using grade 350 steel thick plate as per our customer specifications. The blanks were purchased from an approved material supplier and flame cut to appropriated sizes. Later, they were rough milled, precision CNC turned and precision CNC milled, then drilled and tapped all the internal threads.

We made inspection with CMM, and ensured the precise +/-0.02mm dimensional tolerance requirements. Then we packaged each of unit properly according to the customer's guidelines to protect them during shipping to ensure that they arrived safely at their destination.

If you would like to learn more about this project, or the processes we used to produce it, contact us today.

Custom Machining of Gearbox Housing

| Product Name | Carbon Steel Welding Fixture |

| Product Description | Welding Fixture |

| Capabilities Applied/Processes |

Primary: Flame Cutting Rough Milling Precision Turning Precision Milling Drilling/Tapping Secondary: Packaging/Shipping |

| Equipment Used to Manufacture Part | Horizontal Turning Center, Vertical Milling Center |

| Overall Part Dimensions | 850 x 740 x 120mm |

| Tightest Tolerances | +/-0.02mm |

| Material Used | CS Gr.350 |

| In process testing/inspection performed | Dimensional and Visual Inspection |

| Volume | 5 units |

| Delivery Location | Australia |

| Standards Met | Customer Specifications, 2D CAD Drawing, 3D model |